What Is Nano Graphene Technology?

Green Concrete + Rebar + Building System

Graphene-strengthened concrete admixed with salt water that lowers CO2

3 times stronger, non-corrosive & 4.5 times lighter than Steel

Concrete building system using Basalt-Graphene enhanced concrete and BFRP, reducing materials and labor by 30-50%

Problems With Current Concrete Technology

And Solutions To The Problem

Use of Fresh Water is not Sustainable!

The construction industry uses several billion tons of freshwater annually to wash aggregates and mix/cure concrete.

According to the World Meteorological Organization more than half of the world’s population will lack sufficient drinking water by 2025

How can we innovate Concrete to become Carbon Negative?

By Changing:

The Solution

Basalt-Graphene enhanced concrete with BFRP reduces or eliminates freshwater use

in concrete construction using brackish or saltwater

Basalt-Graphene enhanced concrete sets in HALF the time

4.5 times lighter BRFP requires less labor,

equipment & logistics

Basalt-Graphene admix Certifications

ASTM C94 Standards for Ready-Mixed Concrete

ACI 318 Building Code Requirements for Structural Concrete

TAS105 and 105A Florida Testing Application Standard for withdrawal resistance of fasteners attached to roofing and substrate materials.

Proven in 36 projects over six years.

Adopted by the Florida Department of Transportation

Corrosion Risks

Increased chloride from sustainable concrete ingredients like saltwater, aggregates, and cement causes corrosion.

Basalt Fiber Reinforced Polymer Rebar

Designed to be stronger, lighter, longer-lasting than steel,and resistant to salt and chloride

BFRP Green Rebar Key Features

Designed to be stronger, lighter, longer-lasting than steel, and resistant to salt and chloride

- No Rebar Corrosion

- 4.5 times lighter than Steel

- 2x stronger than Steel

- Much Lower Carbon Footprint than Steel

- High Abrasion Resistance

- High Early Strength

- High-Strength & Volume Stability

- High Resistance to Frost

- High Resistance to Deicer Scaling

Higher R-value for better insulation

Higher R-value for better insulation - Reduces Electromagnetic Interference

- Lower Modulus Elasticity

- Low Permeability and Diffusion

- Basalt-Graphene enhanced concrete improves modulus

- Compaction Without Segregation

Conventional Concrete Comparison

The fresh, cured compressive and tensile mechanical properties of Basalt-Graphene enhanced concrete demonstrate improved performance to conventional concrete.

Accelerated aging, submerged in seawater at high temperatures results yield improved performance to conventional concrete.

Basalt-Graphene enhanced concrete + BFRP Rebar Case Study

In combination with non-corrosive BFRP rebars, Basalt-Graphene enhanced concrete, is used effectively to replace a deficient bridge.

Seawater

Recycled concrete

Recycled asphalt pavement

Basalt-Graphene enhanced concrete with BFRP

Basalt-Graphene enhanced concrete Concrete is Sustainable while reducing set time and labor by 50%

180 BILLION

Potentially CONSERVE 180 billion gallons of freshwater ANNUALLY

90%

REDUCE CARBON FOOTPRINT from the concrete industry

70%

RE-USE 70% of Construction and Demolition WASTE

200%

DOUBLE the lifespan and strength of concrete reinforced structures

30%

LOWERS cement cost 30% Less Portland, No need for Coatings

NON-TOXIC

NON-TOXIC rebar coatings, Graphene antimicrobial properties reduce mold & pathogens

Basalt Fiber Reinforced Polymer Certifications

Designed to be stronger, lighter, longer-lasting than steel,and resistant to salt and chloride

- ACI 318-95, “Building Code Requirements for Concrete” (1995), American Concrete Institute, Detroit, MI, 347 pp.

- ACI 440R-96, “State-of-the-Art Report on Fiber Reinforced Plastic Reinforcement for Concrete Structures” (1996), American Concrete Institute, Detroit, MI, 68 pp.

- “Placing Reinforcing Bars” (1992), Concrete Reinforcing Steel Institute, Schaumburg, IL.

- “ACI 440. 1R-15 “Guide for the Design and Construction of Concrete Reinforced with FRP Bars”. Reported by ACI Committee 440, May 2006.

- “ACI 440.3R-04 “Guide Test Methods for FRP’s Reinforcing or Strengthening Concrete Structures”. Report by ACI Committee 440, October 2004.

- ASTM D7205-06 “Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars”

- ACI 440.5-18 “Specification for Construction with Fiber-Reinforced Polymer Reinforcing Bars”. Reported by ACI Committee 440, July 2008.

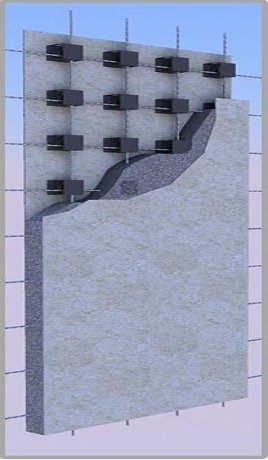

PermaStrongTM Building System

A patented permanent formwork concrete building system of load-bearing walls and floors suitable for any architecture

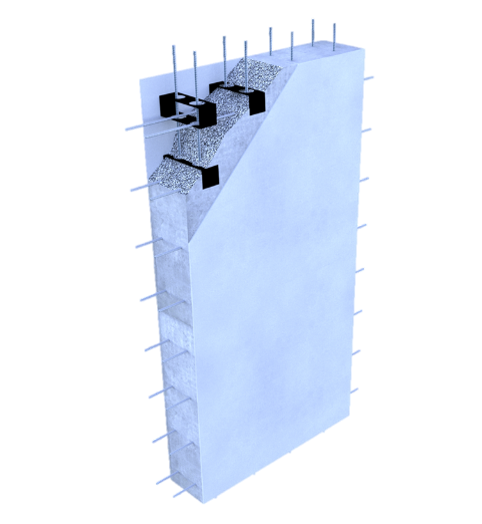

PermaStrong® Building System (detail)

Permanent formwork of bonded recycled polystyrene inserted between 6mm fiber cement sheets

Fiber cement sheets are the Wall surfaces ready for finishing

Reinforced with Basalt Fiber Reinforced Polymer rebar

¤ 3x stronger than steel, 4.5 times lighter, less labor, never rusts

Filled with structural concrete forming a monolithic load-bearing, shear wall structure

PermaStrong Wall Panel Assembly

PermaStrong FLOOR SLAB

-

Construct floors up to 7 meters span using 200mm thick concrete*

-

Wall Panels and service channels interconnect with Floor Slab

-

Tape joint then decorate to finish

* project specific – to be confirmed by engineer

Maximum Strength with Minimum Cost

Delivers high-performance, cost-efficient, lightweight solid partition walls with 20-30% cost savings compared to traditional systems. It’s fast and simple to construct on-site, offering an economical choice for non-load bearing walls

√ Optimum thermal insulation

√ Substantial weight reduction (dead-load)

√ Improved fire rating

√ Maximum sound absorption

√ Basalt-Graphene enhanced concrete Graphene Admix for 2x strength

√ Saving in raw material (no gravel)

√ Savings in steel reinforcement in high rise buildings

√ Savings in transportation (double payload by volume)

√ Savings in craning® (less relocation, larger range)

PermaStrong® Basalt-Graphene enhanced concrete BFRP Advantages

Environmentally Friendly

¤ Uses only sustainable & recycled materials

¤ Basalt-Graphene enhanced concrete, made from biomass, reduces high CO2 of Portland cement

¤ Reduces waste, removal, and landfill costs

Stronger & More Durable,

¤ Designed to withstand 200 MPH Hurricane winds & Earthquakes

¤ 25 PermaStrong™ Homes located where earthquakes occur daily, no damage in three years, so the customer ordered 25 more

¤ Basalt-Graphene enhanced concrete 2X Stronger & Sets in 1/2 the time

Better Economics

¤ 30% – 50% faster construction¤ Labor, scaffold, and equipment reduction

¤ Minimizes on-site work

¤ Requires less skilled labor

¤ No specialist tools or equipment

¤ Less maintenance over its lifetime

¤ Quicker development turnaround

¤ Easier to Bank Finance

PermaStrong® Basalt-Graphene enhanced concrete BFRP Advantages (continued)

¤ Flood Resilient

¤ Quickly cleaned and reoccupied if inundated

¤ No timber, plasterboard or cavities

¤ Termite, Vermin proof, Mold resistant

¤ Termites, borers and rodents resistant

¤ Eliminates physical barriers and hazardous chemical ¤ treatments with frame construction

¤ Basalt-Graphene enhanced concrete is anti-microbial and mold-resistant

¤ Fire Resistant

¤ Non-combustible and highly fire-resistant materials

¤ Energy Efficient

¤ High insulation ratings = less energy cooling and heating

PermaStrong® Construction Process

PermaStrong® Construction Process (continued)

PermaStrong® Construction Process (continued)

6. Concrete Pump Truck to Fill Wall Panels and Roof

One Month to Completed Home

PermaStrong VILLAS

15-STORY PermaStrong APARTMENTS

PermaStrong® Certifications

IBHS GOLD CERTIFIED

MIAMI DADE COUNTY NOA No 18-022.08

ICC REPORT ESR-1668

CalFire Listing – Panel 9140-2180-0003

Florida Code Approval FL 17482

International Building Code 2011